NEWS

Choosing Spiral Wound Gasket with Inner Ring for Industrial Applications

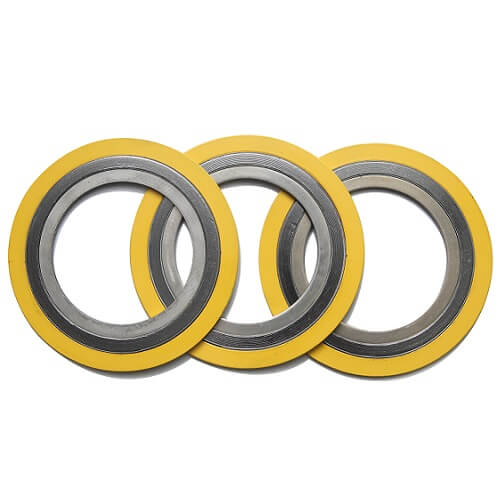

Introduction: Spiral wound gaskets with inner rings offer durable, flexible sealing solutions that reduce maintenance and shutdowns in industrial settings by adapting to thermal, pressure, and vibration stresses.

Daily industrial operations often reveal gaps where equipment efficiency could improve, especially in sealing solutions. Many engineers find themselves addressing issues like leaks caused by thermal expansion, fluctuations in pressure, or vibrations that diminish gasket reliability. Spiral wound gasket manufacturers have long explored ways to bridge these workflow inefficiencies, delivering designs that adapt to operational stresses while maintaining a stable seal. Among the configurations, spiral wound gaskets with inner rings stand out as practical solutions, balancing durability and flexibility seamlessly. Their use ensures smoother maintenance cycles and fewer unscheduled shutdowns, proving invaluable in complex industrial settings where continuous performance is critical.

Key materials and ring configurations in spiral wound gasket with inner ring

Spiral wound gasket suppliers provide a variety of material options tailored to specific industrial environments, where temperature, pressure, and chemical exposure directly influence sealing performance. The inner ring, a critical component, is typically made from stainless steel, carbon steel, or alloy steel, chosen for its strength and resistance to corrosion. This ring supports the gasket’s sealing capability by absorbing load and preventing gasket blowout in high-pressure situations. The combination of profiled metal windings wound with fillers forms a resilient assembly that can recover from thermal cycling and maintain tight tolerances. Spiral wound gasket manufacturers consider these elements carefully to match industry demands, ensuring the inner ring configuration complements the chosen materials and operating conditions. Such precision enhances usability during installation, reducing the need for repetitive torque adjustments. Customizable ring styles and materials also provide adaptability, allowing spiral wound gasket suppliers to meet OEM specifications and diverse application requirements efficiently.

International standards compliance for reliable sealing performance

In highly regulated industries, adherence to international standards shapes the reliability expected from sealing components. Leading spiral wound gasket manufacturers rigorously align their products with standards such as ASME, DIN, JIS, JPI, GB, HG, and SH to guarantee quality and safety across different markets. Compliance involves strict protocols on dimensions, material certification, and performance testing, which assures users that the gasket with inner ring meets global operational demands. This commitment to standardization supports consistent sealing performance despite variable process conditions like shock or vibration, which are common in fields such as petrochemicals and power generation. Moreover, spiral wound gasket suppliers often provide traceability through heat numbers and material test certificates, fostering trust in their products' authenticity and durability. Meeting these various criteria helps reduce operational risks, enabling engineers to focus on process optimization rather than leakage concerns. The ability to rely on certified sealing materials is a foundational aspect for industries where safety and efficiency intersect.

Industry sectors benefiting from spiral wound gaskets with inner ring

Spiral wound gasket manufacturers have tailored their products to serve a broad spectrum of industrial applications where dependable sealing is essential. Sectors such as oil and gas, chemical processing, and petrochemical plants frequently encounter environments with extreme temperatures and pressures, making spiral wound gaskets with inner rings especially suitable. Mining operations also benefit from these gaskets due to their resistance to mechanical shocks and wear. Beyond heavy industry, newer fields like electronics and pharmaceuticals recognize the value of precise gasket design for maintaining clean and controlled environments. Power stations and pipeline infrastructure depend on the gasket's resilience to ensure uninterrupted energy flow, while sectors like food and cement appreciate their compliance with quality standards and ease of installation. The adaptability offered by spiral wound gasket suppliers means these products can be customized for diverse conditions, meeting unique challenges across various operational landscapes. Through this versatile application, users gain both safety and long-term cost efficiency.

Spiral wound gasket manufacturers and suppliers bring thoughtful engineering and regulatory expertise into the manufacturing of spiral wound gaskets with inner rings. Their focus on material quality and standard compliance ensures a practical and durable sealing solution that addresses complex industrial needs. As technologies evolve and operational demands become more exacting, these gaskets are likely to remain a favored choice for industries seeking stable and adaptable sealing options. The fine balance of strength and recovery allows users to experience reduced maintenance interruptions and improved system integrity throughout the lifecycle of equipment. Exploring the benefits offered by spiral wound gasket suppliers may open opportunities for optimized performance and steady operational confidence.

References

Spiral Wound Gaskets – Product Overview– Detailed information on spiral wound gaskets, including materials and applications.

Spiral Wound Gaskets Impact on Industrial Sealing Efficiency– Insights into how spiral wound gaskets enhance sealing performance in industrial settings.

Spiral Wound Gasket Design Selection– Comprehensive guide on selecting the appropriate spiral wound gasket design for various applications.

Spiral Wound Gaskets, Explained– In-depth explanation of spiral wound gaskets, their construction, and usage.

What are Spiral Wound Gaskets?– Overview of spiral wound gaskets, their components, and benefits in industrial applications.