NEWS

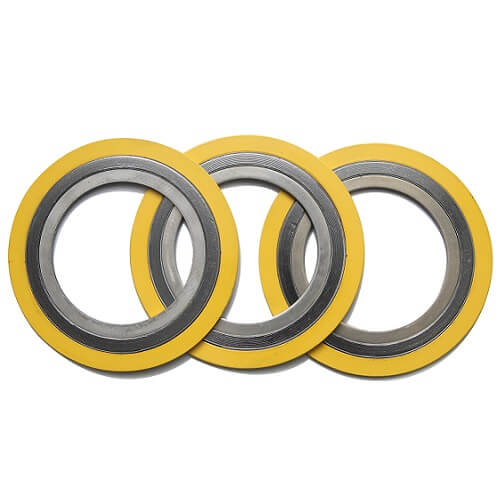

Maximizing Sealing Efficiency with Advanced Spiral Wound Gasket Technology

The industrial sealing landscape has been revolutionized by the advent of spiral wound gaskets, offering unparalleled performance in high-pressure and high-temperature environments. As demand for these critical components grows, spiral wound gasket suppliers have become integral to maintaining operational integrity across various sectors. From oil and gas to chemical processing, the need for reliable sealing solutions has propelled manufacturers to innovate continuously. This article explores the cutting-edge developments in spiral wound gasket technology, comparing different materials and designs, and examining why these gaskets have become the go-to choice for engineers tackling complex sealing challenges.

Table of contents:

The Evolution of Spiral Wound Gaskets in Modern Industrial Settings

Comparing Graphite Gaskets and Spiral Wound Gaskets for Extreme Temperatures

Why Engineers Prefer Spiral Wound Gaskets for Critical Sealing Applications

Innovative Design Features of Next-Generation Semi-Metallic Gaskets

The Evolution of Spiral Wound Gaskets in Modern Industrial Settings

Spiral wound gasket manufacturers have been at the forefront of sealing technology evolution for decades. These gaskets, consisting of a spirally wound metal strip combined with a filler material, have proven their worth in applications where traditional gaskets fall short. As industrial processes become more demanding, spiral wound gasket suppliers have responded by refining their products to withstand ever-increasing pressures and temperatures. The versatility of these gaskets lies in their customizable nature, with spiral wound gasket manufacturers offering various metal and filler material combinations to suit specific industry needs. This adaptability has made spiral wound gaskets indispensable in sectors ranging from petrochemicals to power generation.

Comparing Graphite Gaskets and Spiral Wound Gaskets for Extreme Temperatures

When it comes to extreme temperature applications, both graphite and spiral wound gaskets have their merits. However, spiral wound gaskets often edge out their graphite counterparts in versatility and resilience. Spiral wound gasket suppliers provide products that can withstand a broader range of temperatures and pressures, making them suitable for more diverse applications. While graphite gaskets excel in high-temperature scenarios, they may not offer the same level of compression recovery as spiral wound variants. This recovery property is crucial for maintaining a seal over time, especially in applications subject to thermal cycling. Consequently, many engineers turn to spiral wound gasket manufacturers for solutions that provide both heat resistance and long-term sealing integrity.

Why Engineers Prefer Spiral Wound Gaskets for Critical Sealing Applications

The preference for spiral wound gaskets among engineers stems from their unique construction and performance characteristics. Spiral wound gasket manufacturers design these components to offer excellent resilience and adaptability to flange surface irregularities. This flexibility ensures a tight seal even under fluctuating conditions, a feature particularly valued in critical applications where leakage could lead to safety hazards or production losses. Additionally, spiral wound gasket suppliers often provide products that comply with international standards, making them a reliable choice for global projects. The ability to customize the gasket's metal and filler materials allows engineers to fine-tune the sealing solution to their specific operational requirements, further cementing the popularity of spiral wound gaskets in high-stakes industrial environments.

Innovative Design Features of Next-Generation Semi-Metallic Gaskets

As industry demands evolve, spiral wound gasket manufacturers continue to push the boundaries of design innovation. Next-generation semi-metallic gaskets incorporate advanced features that enhance their already impressive performance. Some spiral wound gasket suppliers now offer products with improved winding profiles that distribute load more evenly, reducing the risk of gasket failure. Others have developed novel filler materials that provide better chemical resistance and longer service life. Innovations in outer ring designs have also emerged, with some spiral wound gasket manufacturers introducing configurations that offer improved centering and handling during installation. These advancements not only improve the gaskets' sealing capabilities but also contribute to easier maintenance and reduced downtime in industrial operations.

The realm of industrial sealing continues to be transformed by the ingenuity of spiral wound gasket manufacturers and suppliers. These components have proven their worth in the most demanding applications, offering a blend of reliability, customization, and performance that is hard to match. As industries push the boundaries of what's possible in terms of pressure, temperature, and chemical resistance, spiral wound gaskets evolve to meet these challenges head-on. The ongoing collaboration between engineers and spiral wound gasket suppliers ensures that these critical components will remain at the forefront of sealing technology, safeguarding industrial processes and driving efficiency for years to come.