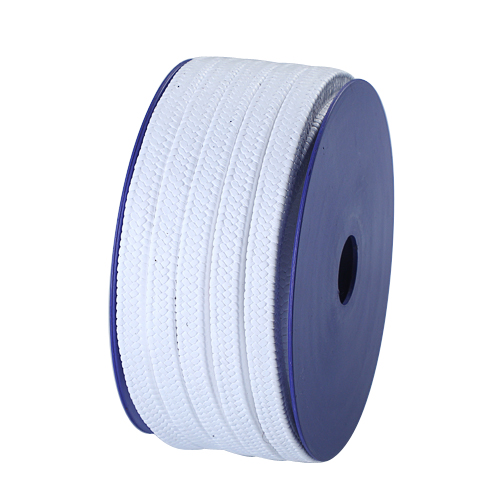

Gland Packing

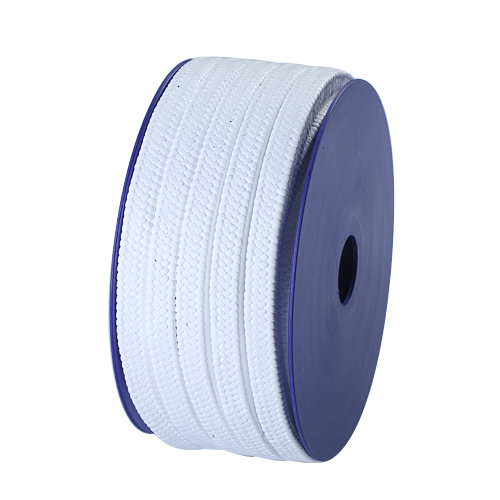

PTFE Packing

- Application:Pump & Valve

Shape:Square | Rectangle - FEEDBACK

Pure dry PTFE braided packing is made of high quality pure dry expanded PTFE yarn withoutany PTFE dispersion and oil lubrication, but with greatly enhanced ability to seal high speedshafts with the addition of inactive and heat resisting agents. Pure dry PTFE braided packingis recommended for chemical engineering, foodstuff, pharmaceutic where contamination isnot allowed. Also it can be applied to seal all chemicals except molten alkali metals. And thepure dry PTFE packing temperature range is from -260'C to 260°℃ (-400° to 500°F)

As Pure dry PTFE braided packing is a kind of braided gland packing without any PTFE dispersion and oil lubrication, so it is very clean and can be used for food and pharmaceutic industry. lt can be used in most chemicals, well suited for diffcult sealing applications andmostly useful in slower shaft speed

Style 2005 pure dry PTFE braided packing is commonly used in valves and lower shaft speedapplications. lt is resistant to most chemicals, aggressive fluids, gases and solvents, with theexception of molten alkali metals. And it is mostly used in those application like pump, valvevessles of corrosive medium in chemical, food and drink industry, parmceutical industry, foodprocessing, paper mills and Fiber plant.

Pure dry PTFE braided packing not suggested for using for molten alkalimetals and fluorine compounds at high temperatures and pressures

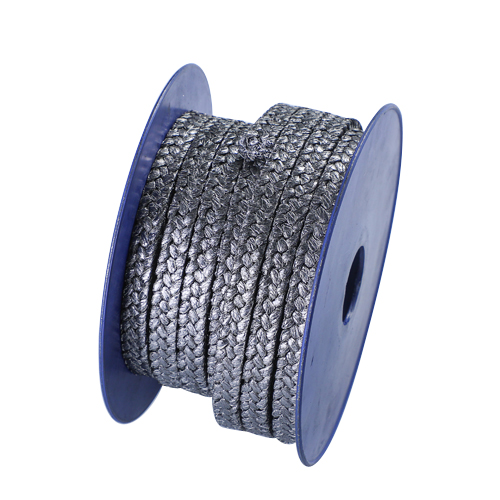

PTFE braided packing with silicone oil impregnation is braided from PTFE fber yarn with silicone oil lubricant. The silicone oil lubricant added in the ptfe fiber packing enhance the heat exchange effective. The PTFE braided packing with silicone oil impregnation has low factor of friction which can prevent deterioration of a surface of a shaft, promotes heat removal from a shaft, even on greater speeds. lt is a braided packing approaches for high concentrate chemical mixes. Manufacturing with silicone rubber core is possible.

PTFE braided packing with silicone oil impregnation is widely used in piston pumps, mixing agitator, the reaction to push, industrial and chemical industries with the valves. And it can be used for a variety of media, including corrosive medium: hot and cold water, steam, solvents,oil, grease, dilute acids and alkalis, salt water, sewage and so on.

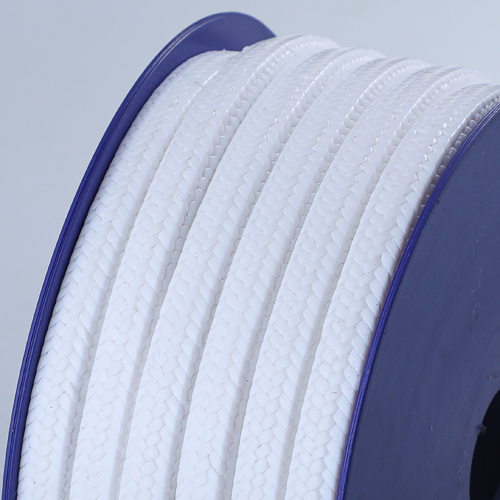

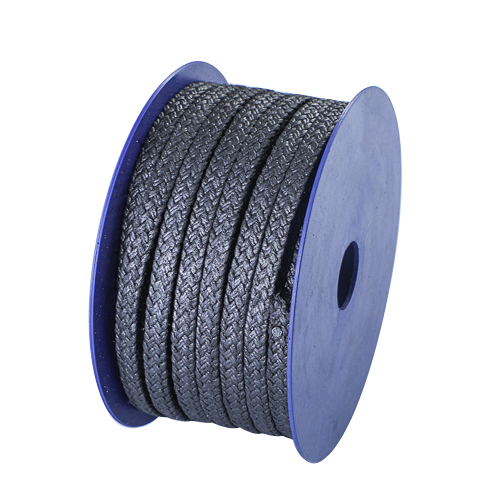

Compared with oil-free PTFE braided packing, PTFE braided packing with silicone oilimpregnation has better lubricity and lower friction coeffcient, So it has low friction fnishand prevents leakage. lt is also well suited for different sealing applications.PTFE FilamentPacking with Silicone Rubber Core PTFE flament packing with silicone rubber core is braidedfrom sintered and highly stretched PTFE multiflament yarns with thoroughPTFE impregnation.The packing is then re-impregnated with PTFE emulsion after braidingprocess. And then The high elastic silicone rubber core can absorb vibration and avoidleakage, the packing is with high cross-section density and structural strength, the packinghas good resistance to compression and extrusion.

The elastic silicone rubber core gives the ptfe filament packing better memory, allowing it to withstand radial shaft motion and vibration while maintaining excellent leakage control with minimal gland adjustments. PTFE flament packing with silicone rubber core is designed for use in general service applications such as agitators, blenders, mixers, or any other applications that undergo shaft deflection in normal operating conditions.

PTFE flament packing with silicone rubber core is one universal braided gland packing,especially suitable for high pressure valves, plunger pumps, mixers, agitators and in the industries where contamination is not permitted, such as food industries, pharmaceutical factories, paper mills, chemical fber plants, etc.

In coils, e.g. 5kgs or 10kgs per coil.

About Us:

Founded and Development

Zhihong Sealing Material Co, LTD was in Cang zhou City, Hebei Province, China. lt covers an area of 20000 square meters and a building area of 2000 square meters. After over 20 years development, we had became one professional manufacturer ofindustrial sealing materials and has the license of import and export. Now we have the fnance department, production department, technology department, quality assurance department,inspection department,foreign trade department and other departments. And we have gaskets, workshop, gasket sheet workshop, braided gland packing workshop.

What We offer

Bythe developing ofour company for over20 years, us Zhihong Sealing Material Co, LTD have full manufacturing lines of industrial sealing products,including industrial sealing gaskets such as non-metal and metal gaskets, compression braided gland packings, So we can service so many different industries such as oil and gas, chemical plants, petrochemical,mining, electronic, power stations, food, cement industries, pharmaceutical, the automotive industry, pipeline & boiler manufacturers and other key industries.

Our Vision and Mission

Zhihong Sealing Material Co, LTD , our success is a result of continually satisfying each of our customers' requirements of high performance sealing products. Our corporate quality policy is committed to offering the highest technology, the best service and the best value. And we had maintained an lSO 9001 quality management system.

Our selling prices will be generally competitive as we believe, however due consideration is always given to providing the most suitable material for the particular applications. Material performance, dependability, available alternatives, technical appraisal and production capability are all areas considered when providing the best possible price for the customer.

CATEGORIES

- Semi-Metallic Gasket

- Spiral Wound Gaskets

- Graphite Gasket

- Metal Jacketed Gaskets

- Metallic Gasket

- Ring Joint Gasket

- Lens Gasket

- Kammprofile Gasket

- Non Metallic Gasket

- PTFE

- Non Asbestos Gasket

- Gland Packing

- PTFE Packing

- Graphite Packing

- Ramie Packing

- PTFE Graphite Packing

- PTFE Graphite Packing With Aramid Corner

- Carbon Packing