Gland Packing

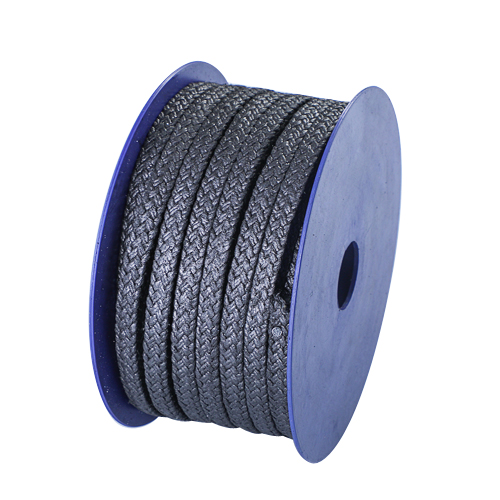

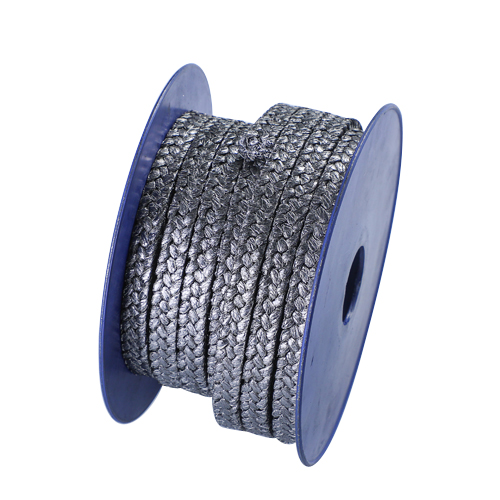

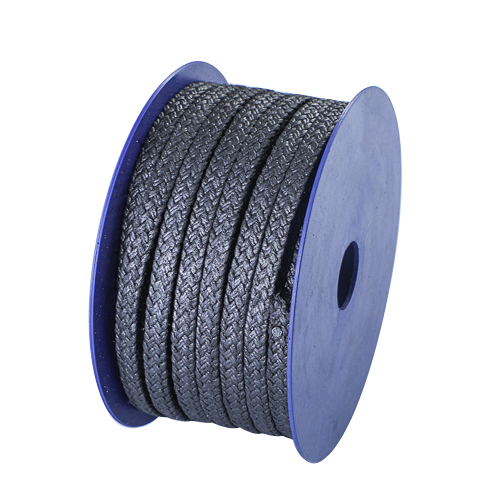

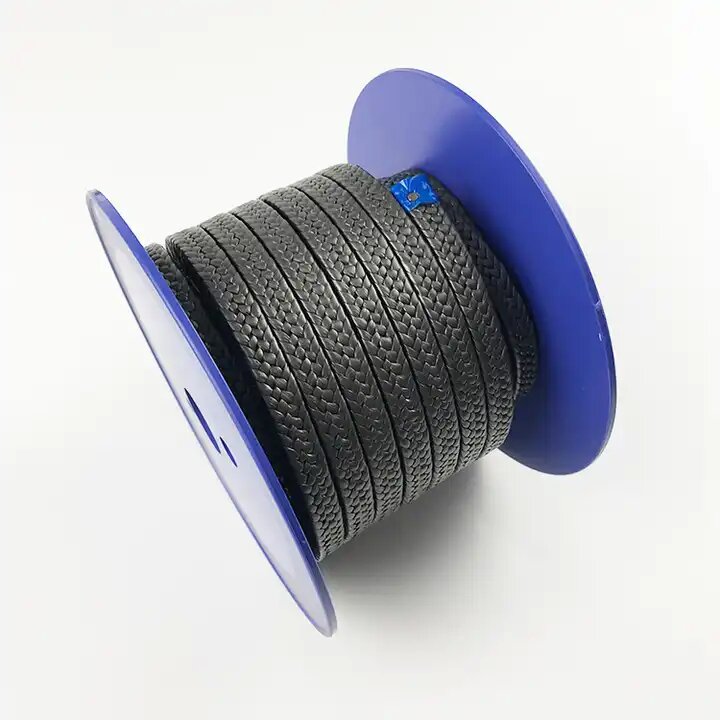

Ramie Packing

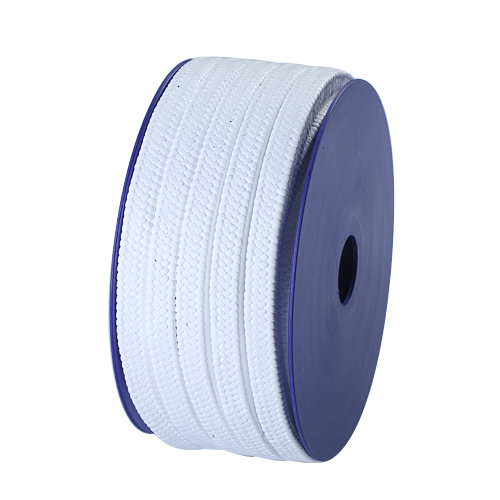

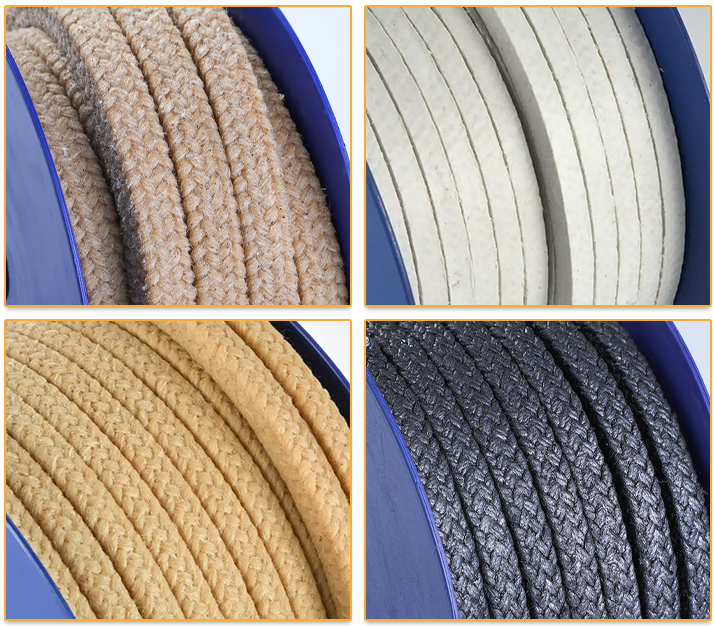

- Impregnated:PTFE | Graphite

Application :Pump | Valve | Shaft

Material:Ramie Fiber/Yarn

Shape:Square | Rectangle - FEEDBACK

Ramie Braided Packing is Made of High-Level Ramie Yarn. Ramie Packing Can Be Divided intoTwo Types According to the Different Working Conditions: Ramie Braided Packing Impregnated PTFE Suspension and impregnated Graphite.

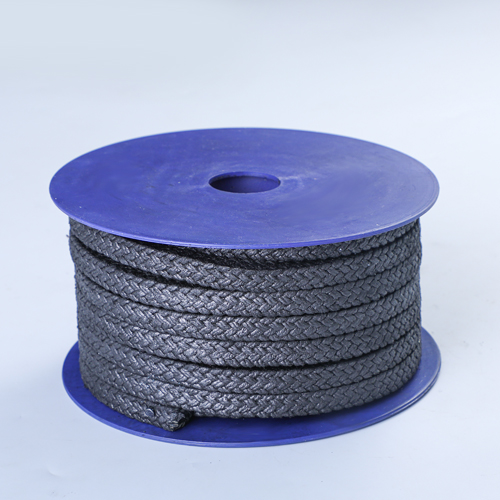

The Ramie Fiber Braided Packing Has Low Friction, Good Lubricity and Corrosion Resistance for Bed Tail Pipe, Rudder Column and Tail Shaft Lining. This Style Package is Also Used in the Pulp and Paper,Water/Wastewater and Mining Industries.

(1) Shaft & Stuffng Box Packing

(2) Stabilizer |Bilge pumps Marine Rudder

(3)Centrifugal |Rotary|Reciprocating Pumps

Density: 1.25g/cm

pH: 4-12

Linear Speed: 10M/S

Temperature: -50'C to 130°

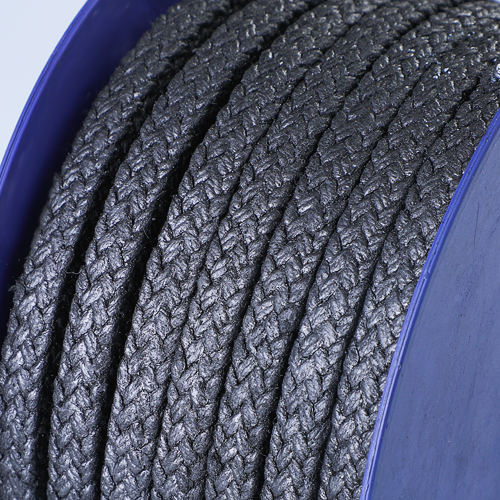

CMaterial: Ramie Fiber with PTFE/GraphiteCore: Red Silicone Rubber

(1) Square |Round

(2)Trapezoidal Rectangular

Valve: 100 Bar

Rotary Pumps: 50

BarReciprocating Pumps: 80 Bar

About Us:

Founded and Development

Zhihong Sealing Material Co, LTD was in Cang zhou City, Hebei Province, China. lt covers an area of 20000 square meters and a building area of 2000 square meters. After over 20 years development, we had became one professional manufacturer ofindustrial sealing materials and has the license of import and export. Now we have the fnance department, production department, technology department, quality assurance department,inspection department,foreign trade department and other departments. And we have gaskets, workshop, gasket sheet workshop, braided gland packing workshop.

What We offer

Bythe developing ofour company for over20 years, us Zhihong Sealing Material Co, LTD have full manufacturing lines of industrial sealing products,including industrial sealing gaskets such as non-metal and metal gaskets, compression braided gland packings, So we can service so many different industries such as oil and gas, chemical plants, petrochemical,mining, electronic, power stations, food, cement industries, pharmaceutical, the automotive industry, pipeline & boiler manufacturers and other key industries.

Our Vision and Mission

Zhihong Sealing Material Co, LTD , our success is a result of continually satisfying each of our customers' requirements of high performance sealing products. Our corporate quality policy is committed to offering the highest technology, the best service and the best value. And we had maintained an lSO 9001 quality management system.

Our selling prices will be generally competitive as we believe, however due consideration is always given to providing the most suitable material for the particular applications. Material performance, dependability, available alternatives, technical appraisal and production capability are all areas considered when providing the best possible price for the customer.

CATEGORIES

- Semi-Metallic Gasket

- Spiral Wound Gaskets

- Graphite Gasket

- Metal Jacketed Gaskets

- Metallic Gasket

- Ring Joint Gasket

- Lens Gasket

- Kammprofile Gasket

- Non Metallic Gasket

- PTFE

- Non Asbestos Gasket

- Gland Packing

- PTFE Packing

- Graphite Packing

- Ramie Packing

- PTFE Graphite Packing

- PTFE Graphite Packing With Aramid Corner

- Carbon Packing