Metallic Gasket

Ring Joint Gasket

- Types:R | RX | BX | SRX | SBX

Applicaiton:RTJ | Tongue and Groove Flange

Material:Carbon | Soft Iron | Stainless Steel

Standard:API | ASME B16.20 - FEEDBACK

China Ring Joint Gasket Manufacturer with High Performance and Affordable Price.

JinSeal Ring Type Joints Are a Kind of Forged Ring Which Will Be Installed into the Machined Groove of an Rtj Flange. After Tightening the Bolts, the Ring Joints Will Be Compressed Between The Flanges into the Grooves and the Rings Will Give an Efficient Sealing Function After Deforming. in This Way, the Metals Material for the API Ring Gaskets is Typically Chosen to Be Softer Than the Flange Material in Order to Prevent Any Damages to The Flanges.

How the Octagonal Ring Type Joint Gasket Works?

The Octagonal ring type gasket is positioned in the actual trapezoidal ring groove on the flange work surface. Whenever the joining bolts are usually tightened, they are really axially compressed and tightened together with the upper and lower trapezoidal grooves of your ring type joint flange, leading to plastic deformation, creating an annular sealing spot, and establishing an initial sealing. After the tension is certainly enhanced, the octagonal ring type gasket is radially widened under the action of the media stress, then the inclined surface area of the gasket and the trapezoidal groove is certainly tighter and makes self-tightening results. However, the increase in media pressure will likely deform the flange and the linking bolt, resulting in a relative divorce between the sealing surfaces, along with a relative reduction in the sealing rate of the gasket. Therefore, the octagonal ring type gasket can be considered to be a semi-self-tightening seal.

Types of Ring Type Joint Gasket

The types of ring type joint gaskets are mainly R type octagonal and Oval section, BX style ring type joint gasket and RX style ring type joint gasket: SRX and SBX type Ring Type Joint Gasket.

R Type Ring Type Joint Gasket

API R type ring type Joint gaskets come in two fundamental types, an oval cross section (Style 302) and an octagonal cross section (Style 301). These types of essential styles are being used in pressures approximately 10,000 psi. The specifications tend to be standard and require specially grooved flanges. The octagonal ring type joint gasket with an octagonal cross section has a bigger sealing performance than the oval and would be the favored gasket. Nevertheless, just the oval ring type joint gasket could be used in the old type round bottom groove. The newer flat bottom groove design and style will agree to either the oval or the octagonal cross section. The sealing surface areas on the ring joint grooves should be smoothly complete to 63 micro inches and to be free of objectionable ridges, tool or chatter scars. They will seal by an initial line contact or a edging action since the compressive press are applied.

BX type Ring Type Joint Gasket

The BX ring type joint gasket is different from the typical oval or octagonal design since it is square in cross section and tapers in each spot. They can just be employed in API 6BX flanges. BX ring type joint gasket is used at pressures as much as 15,000 psi. Common sizes are generally stocked in low carbon steel, 304 and 316.

RX Type Ring Type Joint Gasket

RX ring type joint gaskets are usually related in appearance to the standard octagonal ring joint gasket but their cross section was created to benefit from the included fluid pressure in effecting a seal. They are generally both meant to API 6A and interchangeable with regular octagonal rings for oil field drilling and production applications in API 6B flanges. RX ring type joint gasket is used at pressures approximately 15,000 psi. Regular sizes are supplied in low carbon steel, 304 and 316.

RTJ SRX and SBX Ring Type Joint Gasket

SRX and SBX Ring type joint gasket are manufactured to API 17D and used for Subsea Wellhead and Tree Equipment. The “S” indicates the two types of ring type joint gaskets have cross-drilled holes to make sure that any liquid trapped behind the ring gasket on either side will flow to the ID bore. SRX ring type joint gaskets usually be designed in accordance with API 6BX or API 17D RTJ flanges under water.

Applicable standards

ANSI B16.5-1973 、 JPI-75-15-70 、 GB 699 、 GB1220 、 JB755 、 HG20633-97

Why Choose US

1. Professional

We provide OEM, ODM of Ring joint gaskets for our customers worldwide, highly praised by our customers

2. High quality guarantee.

We strictly carry out ISO quality management system for all production process and raw material incoming.

3. High Quality Material Quarantee

All of our products are high quality material according ASTM

4.After service

24 Hours x 7 days after service

5. Factory Price with Samll MOQ

We promise factory low price with small MOQ.

6.Timely Delivery

For prototype tooling sample lead time 3~7 days For production tooling lead time 10-15 days For order 7-15 days according to quantity.

About Us:

Founded and Development

Zhihong Sealing Material Co, LTD was in Cang zhou City, Hebei Province, China. lt covers an area of 20000 square meters and a building area of 2000 square meters. After over 20 years development, we had became one professional manufacturer ofindustrial sealing materials and has the license of import and export. Now we have the fnance department, production department, technology department, quality assurance department,inspection department,foreign trade department and other departments. And we have gaskets, workshop, gasket sheet workshop, braided gland packing workshop.

What We offer

Bythe developing ofour company for over20 years, us Zhihong Sealing Material Co, LTD have full manufacturing lines of industrial sealing products,including industrial sealing gaskets such as non-metal and metal gaskets, compression braided gland packings, So we can service so many different industries such as oil and gas, chemical plants, petrochemical,mining, electronic, power stations, food, cement industries, pharmaceutical, the automotive industry, pipeline & boiler manufacturers and other key industries.

Our Vision and Mission

Zhihong Sealing Material Co, LTD , our success is a result of continually satisfying each of our customers' requirements of high performance sealing products. Our corporate quality policy is committed to offering the highest technology, the best service and the best value. And we had maintained an lSO 9001 quality management system.

Our selling prices will be generally competitive as we believe, however due consideration is always given to providing the most suitable material for the particular applications. Material performance, dependability, available alternatives, technical appraisal and production capability are all areas considered when providing the best possible price for the customer.

FAQ:

1. What is a Ring Joint Gasket?

A Ring Joint Gasket (RTJ gasket) is a metallic sealing component used to create a leak-proof seal

between flanges in high-pressure and high-temperature environments.

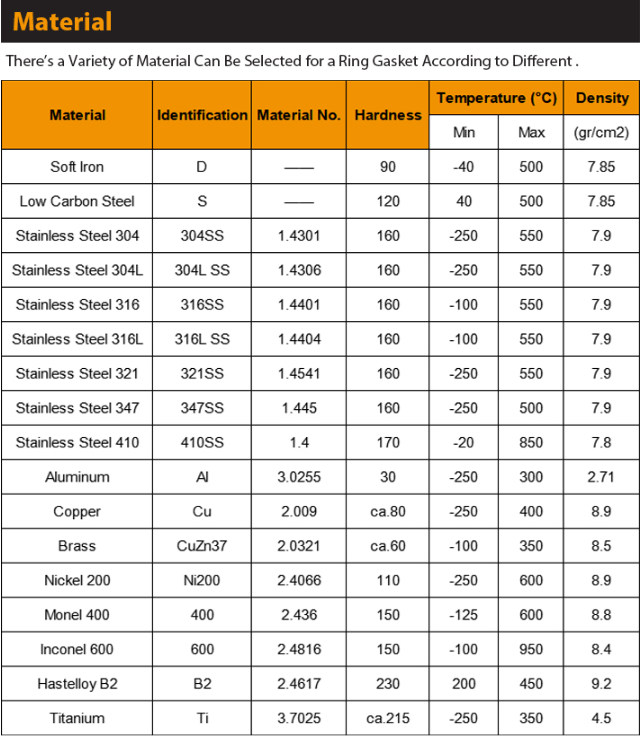

2. What materials are used for RTJ gaskets?

Our RTJ gaskets are made from high-quality materials such as carbon steel, soft iron, and stainless steel,

chosen based on the specific requirements of your application.

3. What types of RTJ gaskets do you offer?

We offer various types of RTJ gaskets, including R, RX, BX, SRX, and SBX types, each designed for

specific flange configurations and service conditions.

4. What industries use RTJ gaskets?

RTJ gaskets are widely used in industries such as oil and gas, petrochemical, power generation, and

chemical processing, where reliable sealing is crucial.

5. Can you customize RTJ gaskets?

Yes, as a leading custom gasket maker, we offer tailored solutions to meet your specific requirements,

including size, shape, and material composition.

6. How do I order RTJ gaskets?

Contact us with your specifications, and our team will provide a customized solution to meet your

sealing needs.

CATEGORIES

- Semi-Metallic Gasket

- Spiral Wound Gaskets

- Graphite Gasket

- Metal Jacketed Gaskets

- Metallic Gasket

- Ring Joint Gasket

- Lens Gasket

- Kammprofile Gasket

- Non Metallic Gasket

- PTFE

- Non Asbestos Gasket

- Gland Packing

- PTFE Packing

- Graphite Packing

- Ramie Packing

- PTFE Graphite Packing

- PTFE Graphite Packing With Aramid Corner

- Carbon Packing