Metallic Gasket

Kammprofile Gasket

- Types:Basic | Loose | Integral

Thickness:2 | 3 | 4mm

Material:Stainless | Carbon | Alloy Stee - FEEDBACK

The Kammprofle Gasket (also Known As Camprofle Gasket) ls Made Up of Serrated Metal Core with a Soft Facing Material Such As graphite, ePTFE. the Flat Metal Core is Machined on Each Contact Face with Concentric Serrations. lt is the Preferred Design when lmproved Performance at Low Seating Stresses ls Needed.

Kammprofle Gaskets Are Always Regarded As a Problem Solver For Heat Exchangers, Large Vessels, and Equipment That Experience Excessive Movement Caused by Thermal Expansion.

Basic Type

Without a Guide Ring, it's Used for Tongue & Groove or Male & Female Flange.Typically Used as a Heat Exchanger Gasket, as an Upgrade to Double Jacketed Gaskets When the Lower Load is Needed

Loose Outer Ring Type

The Loose Outer Ring Type is Regarded as a Problem Solver for Heat Exchangers, Large Vessels and Equipment. The Outer Metallic Ring Works as Centering Ring During installation on a Flange. While the Sealing Lyers on Both Sides Protect the Flange Surface and Reinforced the Seal.

Fixed Outer Ring Type

The Integral Outer Ring Type is for Aligning Purposes. lt's Used in Raised Flanges.

Core Design

The Standard Core Design is Parallel Which Offers the Advantages of Even Stress Distribution Across the Gasket Face. The Convex Core is a Reduced Depth of the Grooves Towards the Profile Center, Ensuring High Seating Stress in the Middle of the Core and is Effective for Low Bolt Load Applications.

(1)Core thickness: 3.0 mm (0.125")

(2)Standard facing thickness is 0.5 mm (0.020")

(3)Custome other thicknesses as request

Product Description

Optimal for Thermal Expansion and Low Stress Environments

Kammprofile gaskets are especially suitable for applications with low seating load but requiring strong sealing, such as

those with thermal cycling. Compared with double-jacketed gaskets, this gasket design delivers enhanced durability and

adaptability. Its performance under movement and stress makes it a go-to solution among gasket suppliers for

industries needing reliability and custom sealing solutions.

Custom Thickness & Material Options for Tailored Solutions

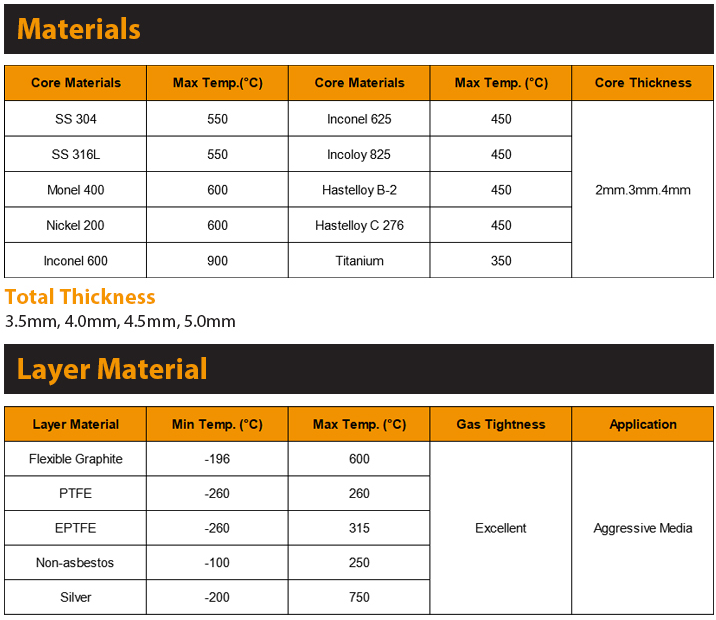

We offer thicknesses of 2 mm, 3 mm, 4 mm. Material facings include graphite or ePTFE, and metal cores can be

stainless steel, carbon steel or alloy steel. Zhihong Sealing provides OEM/ODM services; we can manufacture to

your drawing or specification. Ensure perfect compatibility with your flange type and operational environment.

Durable Serrated Metal Core for Enhanced Seal Performance

Our Kammprofile Gasket features a serrated metal core (stainless, carbon or alloy steel) with concentric grooves that

improve grip and sealing capacity. The soft facings—graphite or ePTFE—help to protect flange surfaces and enhance

seal under low seating stress. This design ensures robust performance even in demanding conditions.

About Us:

Founded and Development

Zhihong Sealing Material Co, LTD was in Cang zhou City, Hebei Province, China. lt covers an area of 20000 square meters and a building area of 2000 square meters. After over 20 years development, we had became one professional manufacturer ofindustrial sealing materials and has the license of import and export. Now we have the fnance department, production department, technology department, quality assurance department,inspection department,foreign trade department and other departments. And we have gaskets, workshop, gasket sheet workshop, braided gland packing workshop.

What We offer

Bythe developing ofour company for over20 years, us Zhihong Sealing Material Co, LTD have full manufacturing lines of industrial sealing products,including industrial sealing gaskets such as non-metal and metal gaskets, compression braided gland packings, So we can service so many different industries such as oil and gas, chemical plants, petrochemical,mining, electronic, power stations, food, cement industries, pharmaceutical, the automotive industry, pipeline & boiler manufacturers and other key industries.

Our Vision and Mission

Zhihong Sealing Material Co, LTD , our success is a result of continually satisfying each of our customers' requirements of high performance sealing products. Our corporate quality policy is committed to offering the highest technology, the best service and the best value. And we had maintained an lSO 9001 quality management system.

Our selling prices will be generally competitive as we believe, however due consideration is always given to providing the most suitable material for the particular applications. Material performance, dependability, available alternatives, technical appraisal and production capability are all areas considered when providing the best possible price for the customer.

FAQ

1)What is a Kammprofile Gasket and how does it differ from a spiral wound gasket?

A Kammprofile gasket features a serrated metal core with soft facing materials (graphite or ePTFE), while a spiral

wound gasket is wound with metal strip and filler. Kammprofile is preferred when low seating stress and flange

protection are needed.

2) Which materials are available for the metal core and facing?

The metal cores can be stainless steel, carbon steel or alloy steel. Facings can be graphite or ePTFE. These options

are used by leading metal gasket manufacturers and gasket suppliers to adapt to different media and temperatures.

3)Can the Kammprofile Gasket be customized?

Yes. Zhihong Sealing offers OEM/ODM customization. We can manufacture kammprofile gaskets to your drawing,

desired thickness (2-4 mm), flange type (basic, loose outer ring, integral) and material combination.

4)What applications are ideal for using a Kammprofile Gasket?

Heat exchangers, large pressure vessels, equipment that experiences thermal expansion or movement. When low seat

load and reliable sealing under fluctuating conditions are required, Kammprofile gaskets from reliable gasket suppliers

perform very well.

CATEGORIES

- Semi-Metallic Gasket

- Spiral Wound Gaskets

- Graphite Gasket

- Metal Jacketed Gaskets

- Metallic Gasket

- Ring Joint Gasket

- Lens Gasket

- Kammprofile Gasket

- Non Metallic Gasket

- PTFE

- Non Asbestos Gasket

- Gland Packing

- PTFE Packing

- Graphite Packing

- Ramie Packing

- PTFE Graphite Packing

- PTFE Graphite Packing With Aramid Corner

- Carbon Packing