Semi-Metallic Gasket

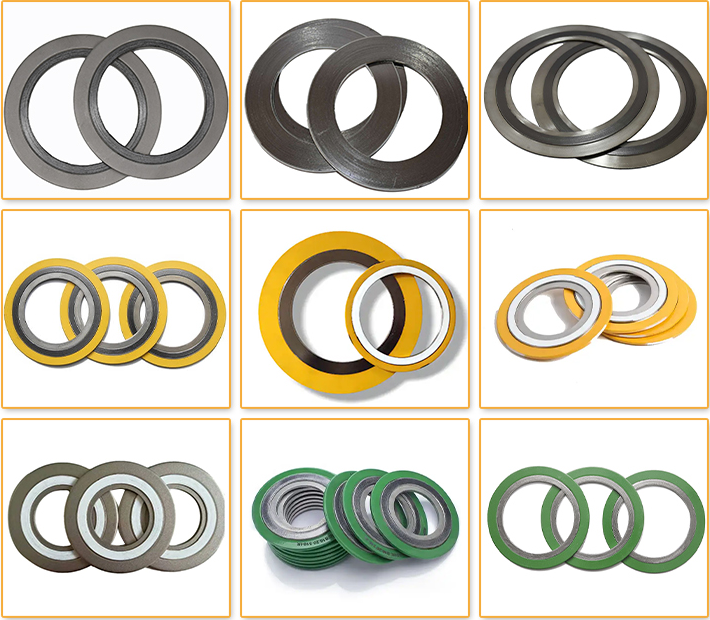

Spiral Wound Gaskets

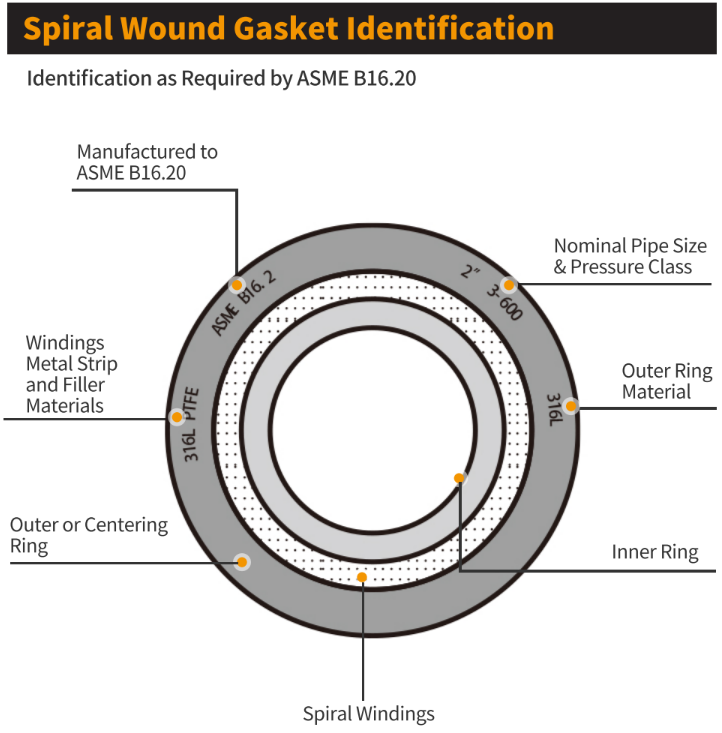

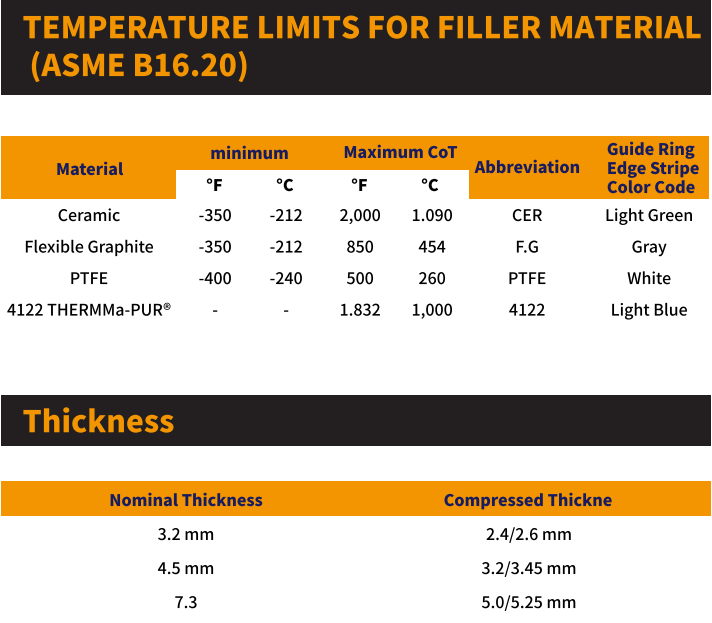

- Material:Stainless | Carbon | Alloy Steel

Types:Inner Ring | Outer Ring | Winding | Inner Ring &Outer Ring|

Pressure Rating:As Standard

Color Code:As Standard

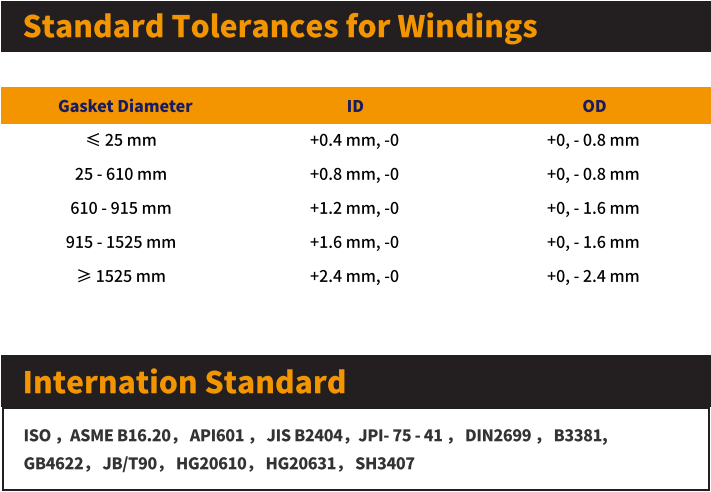

internation standard:ASME | DIN | JIS| JPI|GB| HG| SH - FEEDBACK

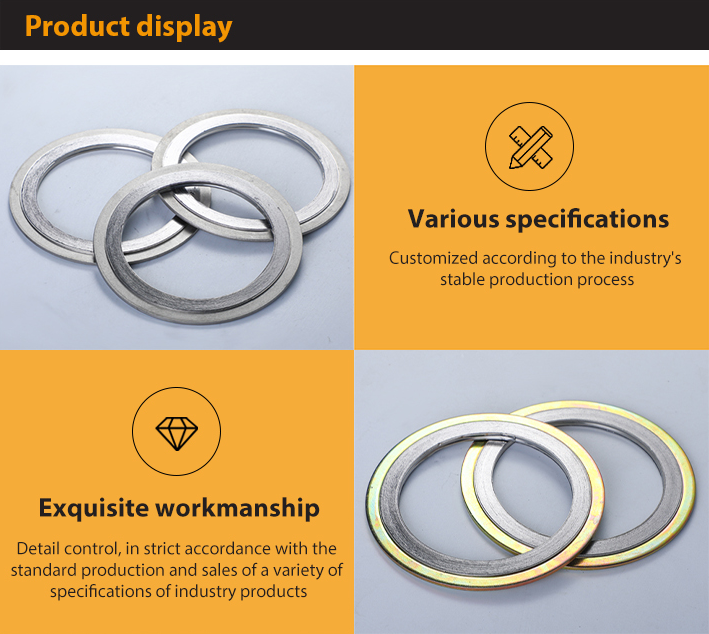

Zhihong Seal, One of the Leading Spiral Wound Gasket Manufacturers InChina, Has Been Involved in SWG Gasket for over 20 Years. Metal SpiralWound Gasket Offers High Temperature and Pressure Sealing With GoodRecovery Performance, Due to These Characteristics, Gasket Sealer isWidely Used in the Applications of Extreme Temperature or HighPressure, Shock, or Vibration Due to lts Best Resistance Property whenCompared with Other Gaskets Types.

Product Description:

What Is a Spiral Wound Gasket

A spiral wound gasket is built from profiled metal windings and a compressible filler to deliver reliable

sealing under thermal cycling and bolt-load variations. Its robust construction helps maintain tightness

in flanged joints across demanding services. (General technical description consistent with site context;

no unverified specs stated.

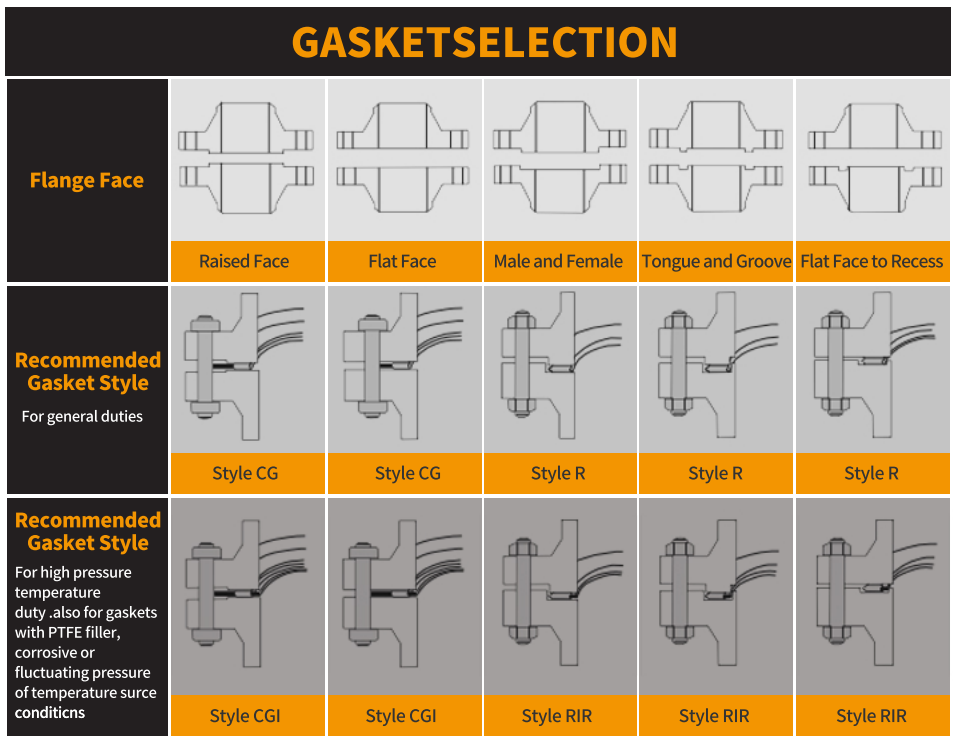

Types and Materials You Can Specify

Choose the construction that matches your flange and service: inner-ring, outer-ring, winding, or inner

and outer ring styles. Materials include stainless, carbon, and alloy steel, with pressure rating and color

coding per standard. International standards supported include ASME, DIN, JIS, JPI, GB, HG, and SH.

Where These Gaskets Work Best

Our Spiral Wound Gaskets serve oil and gas, chemical and petrochemical plants, mining, electronics,

power stations, food, cement, pharmaceuticals, automotive, and pipeline & boiler manufacturers

covering the full spectrum of process-industry sealing scenes.

Product Advantages:

Standards-Ready Compliance

Our Spiral Wound Gaskets are engineered to match ASME, DIN, JIS, and other global specs, so your

flange joints pass audits with less rework. Choosing a spiral wound gasket from a seasoned gasket

manufacturer and gasket supplier shortens approval and start-up time.

Robust Seal Under Cycling

Profiled metal windings with compressible filler keep a tight seal while bolts relax and temperatures swing.

In steam, solvents, or light hydrocarbons, each spiral wound gasket maintains gasket stress, reducing leaks

and unplanned downtime across process units.

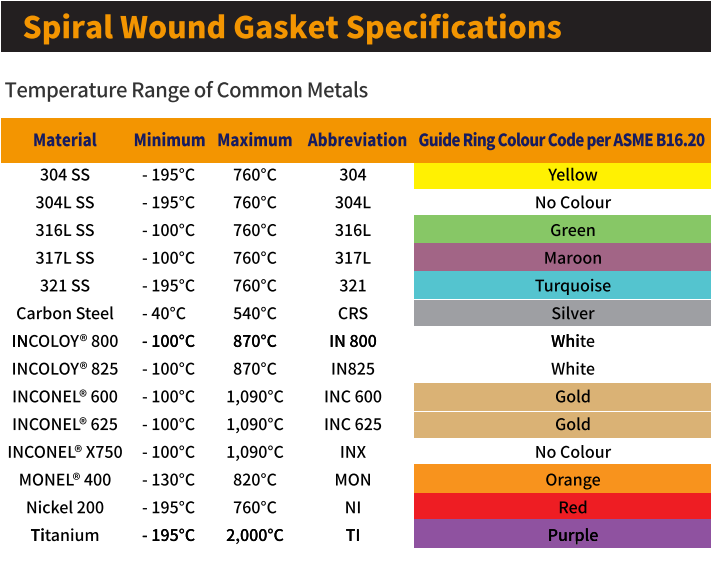

Material Versatility

Select stainless, carbon, or alloy steel to balance corrosion resistance, strength, and cost. Our Spiral Wound

Gaskets pair metals with appropriate fillers to suit media and temperature, giving designers flexible options

without compromising regulatory requirements.

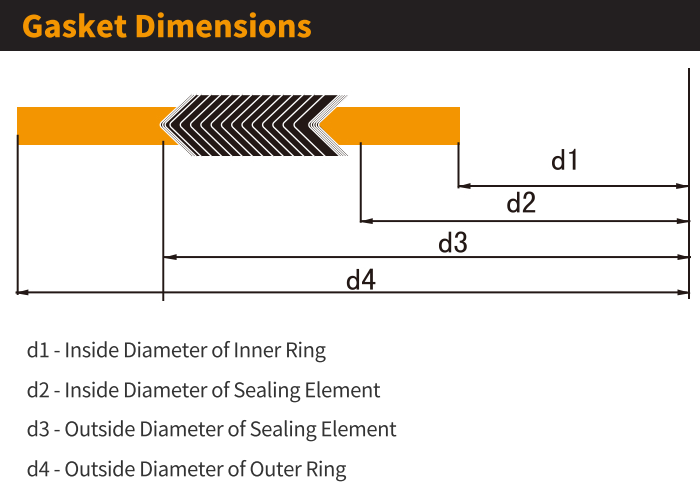

Precision Fit and Installation

Tight tolerances and clean faces help gaskets seat quickly and evenly, cutting assembly time and re-torque

visits. With inner or outer ring options, each Spiral Wound Gasket build promotes centering and flange

protection for dependable, repeatable installs.

OEM-Ready Customization

From drawings to non-standard sizes, we tailor winding, ring style, and markings for your project. As

experienced gasket manufacturers, we respond fast with spec-correct prototypes, helping EPCs and

MRO teams standardize a spiral wound gasket across sites.

Reliable Supply and QC

Integrated lines and documented inspections deliver consistent quality lot to lot. Traceable heat numbers

and MTCs let your team verify each shipment of Spiral Wound Gaskets, while our gasket supplier model

keeps lead times predictable for shutdown planning.

About Us:

Founded and Development

Zhihong Sealing Material Co, LTD was in Cang zhou City, Hebei Province, China. lt covers an area of 20000 square meters and a building area of 2000 square meters. After over 20 years development, we had became one professional manufacturer ofindustrial sealing materials and has the license of import and export. Now we have the fnance department, production department, technology department, quality assurance department,inspection department,foreign trade department and other departments. And we have gaskets, workshop, gasket sheet workshop, braided gland packing workshop.

What We offer

Bythe developing ofour company for over20 years, us Zhihong Sealing Material Co, LTD have full manufacturing lines of industrial sealing products,including industrial sealing gaskets such as non-metal and metal gaskets, compression braided gland packings, So we can service so many different industries such as oil and gas, chemical plants, petrochemical,mining, electronic, power stations, food, cement industries, pharmaceutical, the automotive industry, pipeline & boiler manufacturers and other key industries.

Our Vision and Mission

Zhihong Sealing Material Co, LTD , our success is a result of continually satisfying each of our customers' requirements of high performance sealing products. Our corporate quality policy is committed to offering the highest technology, the best service and the best value. And we had maintained an lSO 9001 quality management system.

Our selling prices will be generally competitive as we believe, however due consideration is always given to providing the most suitable material for the particular applications. Material performance, dependability, available alternatives, technical appraisal and production capability are all areas considered when providing the best possible price for the customer.

FAQ:

1) What is a spiral wound gasket?

A spiral wound gasket combines profiled metal windings with a compressible filler to maintain tightness

underbolt-load and temperature changes. It is widely used in process-industry flange joints for reliable,

repeatable sealing.

2) Which standards do you support?

We manufacture Spiral Wound Gaskets to mainstream global standards, including ASME, DIN, JIS, JPI,

GB, HG and SH. Tell us the target standard and service conditions, and we’ll match a spec-correct build.

3) What ring configurations are available?

You can select inner-ring, outer-ring, winding-only, or inner-and-outer-ring constructions. The choice

depends on flange type and operating conditions, helping ensure centering, flange protection and stable

sealing performance.

4) Which materials can I choose?

We supply stainless, carbon and alloy-steel options to balance corrosion resistance, strength and cost.

Share your medium and temperature range, and we’ll recommend a suitable spiral wound gasket material

pairing.

5) Do you provide OEM/ODM and non-standard sizes?

Yes. As a seasoned gasket manufacturer, we handle OEM/ODM and non-standard customization by

drawings, including size, ring style and marking, to meet project requirements across global sites.

6) What industries do you serve?

Our Spiral Wound Gaskets are used across oil and gas, chemicals and petrochemicals, mining, electronics,

power stations, food, cement, pharmaceuticals, automotive, and pipeline and boiler manufacturing.

CATEGORIES

- Semi-Metallic Gasket

- Spiral Wound Gaskets

- Graphite Gasket

- Metal Jacketed Gaskets

- Metallic Gasket

- Ring Joint Gasket

- Lens Gasket

- Kammprofile Gasket

- Non Metallic Gasket

- PTFE

- Non Asbestos Gasket

- Gland Packing

- PTFE Packing

- Graphite Packing

- Ramie Packing

- PTFE Graphite Packing

- PTFE Graphite Packing With Aramid Corner

- Carbon Packing